Mantis 10 Single Drive 48V 800W Wiring Diagram Guide SGTEC07

Mantis 10 Single Drive 48V 800W Wiring Diagram Guide SGTEC07

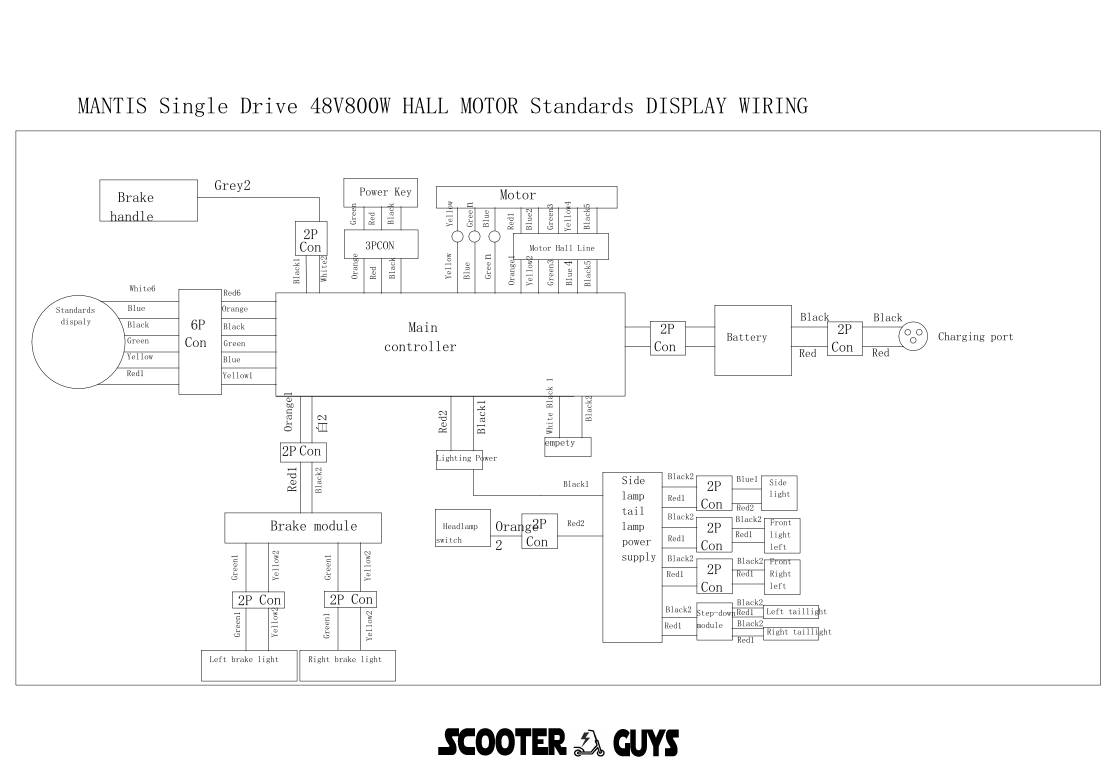

This guide provides a comprehensive wiring diagram for the Mantis 10 electric scooter with a single drive 48V 800W brushless motor with a hall sensor. The wiring involves the standard display, main controller, various connectors, brake module, brake handle, headlamp, power key, 48V battery, and charge port.

Components:

- Standard Display:

- Connection Type: 6-pin connector (6P)

- Main Controller:

- Function: Central processing unit for controlling the scooter

- Motor:

- Model: 800W Brushless Motor with Hall Sensor

- Voltage: 48V

- Brake Module:

- Connection Type: 2-pin connector (2P)

- Brake Handle:

- Connection Type: 2-pin connector (2P)

- Headlamp:

- Connection Type: 2-pin connector (2P)

- Power Key:

- Connection Type: 3-pin connector (3P)

- 48V Battery:

- Connection Type: 2-pin connector (2P)

- Charge Port:

- Connection Type: 2-pin connector (2P)

- Motor Hall Line:

- Connection Type: Hall sensor line

Wiring Diagram:

Below is a detailed step-by-step guide to wiring each component:

- Connecting the Standard Display to the Main Controller:

- The standard display uses a 6-pin connector (6P).

- Wire color coding and pin configuration:

- Red (Power +5V): Connect to the +5V power output on the main controller.

- Black (Ground): Connect to the ground terminal on the main controller.

- Green (Signal 1): Connect to the first signal input on the main controller.

- Yellow (Signal 2): Connect to the second signal input on the main controller.

- Blue (Communication): Connect to the data communication port on the main controller.

- White (Backlight Control): Connect to the backlight control input on the main controller.

- Connecting the Brake Module to the Main Controller:

- The brake module uses a 2-pin connector (2P).

- Wire color coding and pin configuration:

- Red (Power +5V): Connect to the +5V power output on the main controller.

- Black (Ground): Connect to the ground terminal on the main controller.

- Connecting the Brake Handle to the Main Controller:

- The brake handle uses a 2-pin connector (2P).

- Wire color coding and pin configuration:

- Red (Brake Signal): Connect to the brake signal input on the main controller.

- Black (Ground): Connect to the ground terminal on the main controller.

- Connecting the Headlamp to the Main Controller:

- The headlamp uses a 2-pin connector (2P).

- Wire color coding and pin configuration:

- Red (Power +): Connect to the headlamp power output on the main controller.

- Black (Ground): Connect to the ground terminal on the main controller.

- Connecting the Power Key to the Main Controller:

- The power key uses a 3-pin connector (3P).

- Wire color coding and pin configuration:

- Red (Power +): Connect to the main power input on the main controller.

- Black (Ground): Connect to the ground terminal on the main controller.

- Green (Signal): Connect to the power key signal input on the main controller.

- Connecting the 48V Battery to the Main Controller:

- The 48V battery uses a 2-pin connector (2P).

- Wire color coding and pin configuration:

- Red (Battery +): Connect to the battery positive terminal on the main controller.

- Black (Battery -): Connect to the ground terminal on the main controller.

- Connecting the Charge Port to the Main Controller:

- The charge port uses a 2-pin connector (2P).

- Wire color coding and pin configuration:

- Red (Charging +): Connect to the charging positive terminal on the main controller.

- Black (Charging -): Connect to the ground terminal on the main controller.

- Connecting the Motor Hall Line to the Main Controller:

- The motor hall line connects the hall sensors of the motor to the main controller.

- Hall sensor connection details:

- Red (Hall Power +5V): Connect to the +5V hall sensor power output on the main controller.

- Black (Ground): Connect to the hall sensor ground terminal on the main controller.

- Green (Hall Sensor A): Connect to the hall sensor A input on the main controller.

- Yellow (Hall Sensor B): Connect to the hall sensor B input on the main controller.

- Blue (Hall Sensor C): Connect to the hall sensor C input on the main controller.

Wiring Connections:

- Standard Display to Main Controller (6P):

- Red: +5V Power

- Black: Ground

- Green: Signal 1

- Yellow: Signal 2

- Blue: Communication

- White: Backlight Control

- Brake Module to Main Controller (2P):

- Red: +5V Power

- Black: Ground

- Brake Handle to Main Controller (2P):

- Red: Brake Signal

- Black: Ground

- Headlamp to Main Controller (2P):

- Red: Power +

- Black: Ground

- Power Key to Main Controller (3P):

- Red: Power +

- Black: Ground

- Green: Signal

- 48V Battery to Main Controller (2P):

- Red: Battery +

- Black: Battery –

- Charge Port to Main Controller (2P):

- Red: Charging +

- Black: Charging –

- Motor Hall Line to Main Controller:

- Red: +5V Power

- Black: Ground

- Green: Hall Sensor A

- Yellow: Hall Sensor B

- Blue: Hall Sensor C

Tips:

- Ensure all connections are secure and insulated to prevent short circuits.

- Follow the color-coding strictly to avoid any miswiring.

- Refer to the user manual for specific details regarding your model.

- Double-check all connections before powering on the scooter to ensure everything is correctly wired.

This detailed wiring diagram and guide should help in successfully connecting and configuring the components of your Mantis 10 electric scooter with a single drive 48V 800W motor.